When bearings are used in low-temperature environments, the clearance of the bearings is typically negative when they leave the factory.

Bearings are designed with a certain amount of internal clearance, which is the space between the rolling elements (balls or rollers) and the raceways in which they operate. This internal clearance allows for thermal expansion of the bearing components during operation.

In low-temperature environments, the materials used in the bearing components tend to contract due to the decreased temperature. This contraction can reduce the internal clearance of the bearing, potentially leading to increased friction, decreased lubrication, and premature wear.

To compensate for the contraction and ensure proper clearance in low-temperature conditions, bearing manufacturers often design and produce bearings with negative clearance. This means that the initial clearance is smaller than the normal operating clearance at room temperature.

By starting with a negative clearance, the bearing's internal components can expand as the temperature rises during operation, allowing for the desired operating clearance to be achieved. This approach helps maintain proper lubrication, reduce friction, and prevent potential damage to the bearing in low-temperature environments.

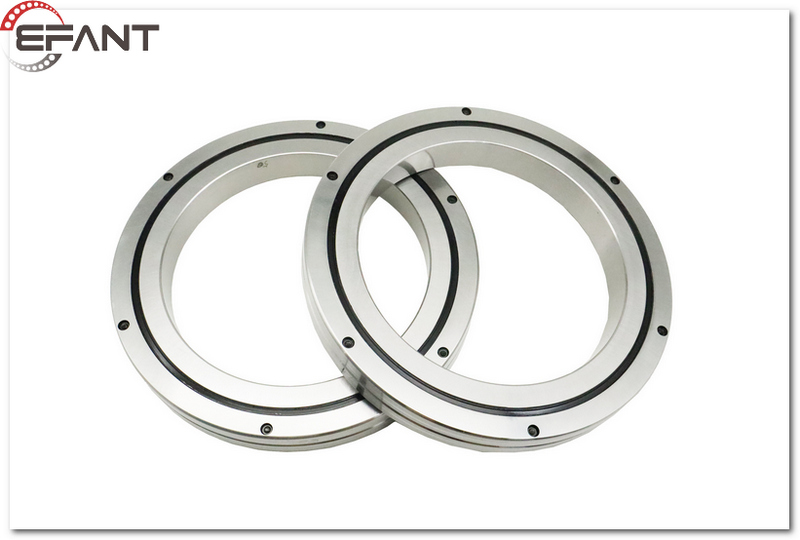

Our main products are RB, RA, CRBH, SX, RU, XU, XSU series crossed cylindrical roller bearings, YRT, YRTS, ZKLDF series rotary table bearings. Many models are bulk on the stock.

You can contact us if you have any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request