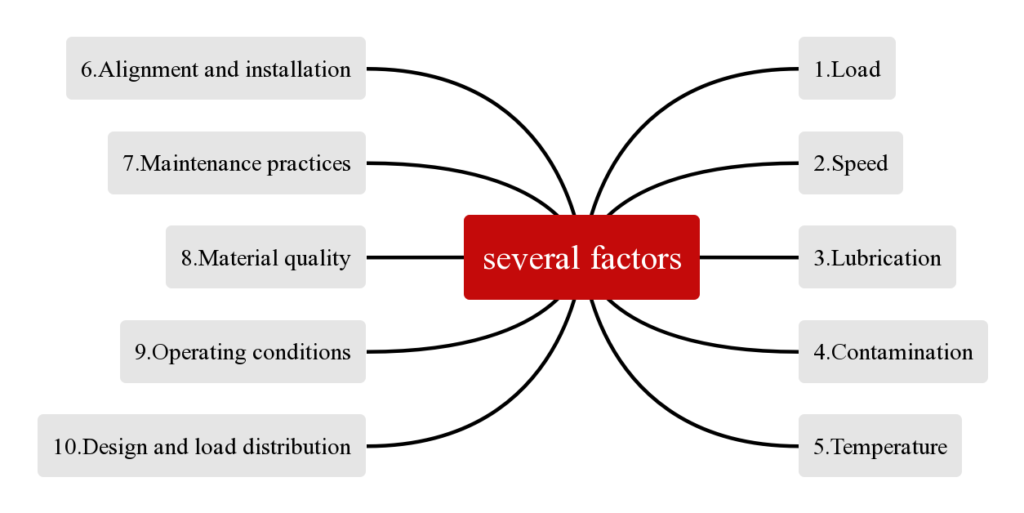

The service life of bearings can be influenced by several factors, including:

1.Load: The magnitude and direction of the load placed on the bearing can significantly affect its service life. Higher loads or sudden changes in load can accelerate wear and fatigue, reducing the bearing's lifespan.

2.Speed: The rotational speed at which the bearing operates can impact its service life. Higher speeds generate greater forces and generate more heat, which can lead to increased wear and potential failure.

3.Lubrication: Proper lubrication is crucial for reducing friction and wear in bearings. Inadequate or improper lubrication can result in increased friction, overheating, and premature failure.

4.Contamination: Foreign particles, such as dust, dirt, or debris, can enter the bearing and cause abrasion, corrosion, or blockages. This contamination can accelerate wear and reduce the bearing's service life.

5.Temperature: Excessive temperatures can adversely affect the material properties of bearings, leading to premature wear and failure. High temperatures can cause the lubricant to break down or evaporate, resulting in inadequate lubrication.

6.Alignment and installation: Incorrect installation or misalignment of bearings can lead to uneven loading, increased friction, and premature failure. Proper alignment and installation techniques should be followed to ensure optimal performance and longevity.

7.Maintenance practices: Regular maintenance, such as cleaning, lubrication, and inspection, is essential for maximizing the service life of bearings. Neglecting maintenance can allow issues to go unnoticed, leading to accelerated wear and potential failure.

8.Material quality: The quality and composition of the bearing material can impact its durability. High-quality bearings made from appropriate materials for the application tend to have longer service lives.

9.Operating conditions: Environmental factors, such as humidity, corrosive atmospheres, or exposure to chemicals, can affect the service life of bearings. Harsh operating conditions can accelerate wear and degradation.

10.Design and load distribution: The design of the bearing and its load distribution capabilities play a crucial role in its service life. Bearings designed to handle specific loads and operating conditions are more likely to have longer lifespans.

It's important to note that these factors are interrelated and can collectively influence the service life of bearings. Manufacturers often provide guidelines and specifications for optimal operating conditions to maximize the lifespan of bearings in specific applications.

Our main products are RB, RA, CRBH, SX, RU, XU, XSU series crossed cylindrical roller bearings, XR, JXR crossed tapered roller bearings, YRT, YRTS, ZKLDF series rotary table bearings. Many models are bulk on the stock. Diameter range from 20 mm to 2,000 mm. All products are produced by advanced CNC machines and are 100% inspected. The Precision class is P5 P4 and P2. The warranty is 12 months.

You can contact us anytime if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request