From a literal perspective, there is only one word difference between turntable bearings and turntable bearings, both of which are rolling bearings used for mechanism support and rotation. However, for the mechanical industry, there is an essential difference between the two. The former specifically refers to series standardized high-precision rotary bearings, while the latter includes large and extra large bearings used for ordinary and precision level rotation.

Turntable bearing is a precision bearing with a special structure that can simultaneously withstand comprehensive loads such as axial load, radial load, and overturning torque. It integrates functions such as support, rotation, transmission, and fixation. The turntable bearings are mostly made of bearing steel GCr15SiMn fully quenched, with good material, high hardness, wear resistance, and high structural stability; The turntable bearing is made of surface quenched steel, which only undergoes surface heat treatment. It is impact resistant and has good material processing performance. Relatively speaking, its structural stability is inferior to that of turntable bearings. The precision of the turntable bearings is high, mostly in the micrometer level, mainly achieved through grinding and processing.

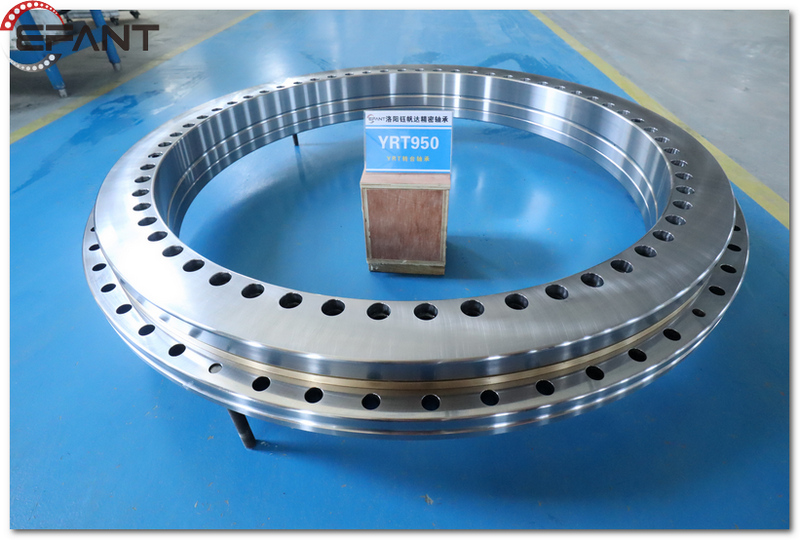

The rotary table bearing relies on its own characteristics and strict processing technology, can also withstand comprehensive directional loads, and has high rotational accuracy. The structure of the rotary table bearing varies greatly. The YRT rotary table bearing belongs to the ultra-high precision type (close to P2 level) rotary table bearing, which is composed of 2 sets of axial rollers and 1 set of radial roller bearings. This series of bearings has high processing difficulty and precision requirements, and is suitable for precision CNC machine tools, measuring instruments, military equipment, etc;

Except for precision turntables, turntable bearings generally have slightly lower accuracy requirements and are at the level of threads. A few threads or even tens of threads are normal, and they are mainly machined by turning. Rotary table bearing is a special large bearing structure that can simultaneously withstand large axial loads, radial loads, and overturning moments. It integrates multiple functions such as support, rotation, transmission, and fixation, and is equipped with mounting holes, lubricating oil, and sealing devices with internal or external tooth structures. It is easy to install and use, saves costs on surrounding components, and is mainly used in large equipment such as lifting and transportation machinery, mining machines, construction machinery, port machinery, and wind power generation.

Please feel free to contact us if you have any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request