Large copiers often come equipped with advanced features, such as automatic duplexing (double-sided printing), stapling and binding options, and advanced finishing capabilities. They may also have additional input and output trays to handle large paper volumes and complex print jobs.

In terms of speed, large copiers can print and copy at extremely high rates, ranging from 50 to 200 pages per minute or more. They may also have multiple printing engines, allowing them to handle multiple print jobs simultaneously.

There are a few reasons why large copiers might choose roller bearings instead of ball bearings:

1.Load Capacity: Roller bearings have a higher load capacity than ball bearings. This means that they can support heavier loads without deforming or breaking. This is important for large copiers that need to handle heavy paper stacks and other components.

2.Radial and Thrust Loads: Roller bearings can handle both radial and thrust loads, while ball bearings are better suited for radial loads only. Copiers often require bearings that can handle both types of loads, which makes roller bearings a better choice.

3.Misalignment: Roller bearings can also handle misalignment better than ball bearings. Copiers are often subject to misalignment due to the vibration and movement that occurs during operation. Roller bearings can compensate for this misalignment, which helps to extend their lifespan and reduce maintenance requirements.

4.Durability: Roller bearings are generally more durable than ball bearings. They have a larger contact area, which distributes the load more evenly and reduces the risk of damage or wear. This is important for copiers that are used frequently and require reliable performance over a long period of time.

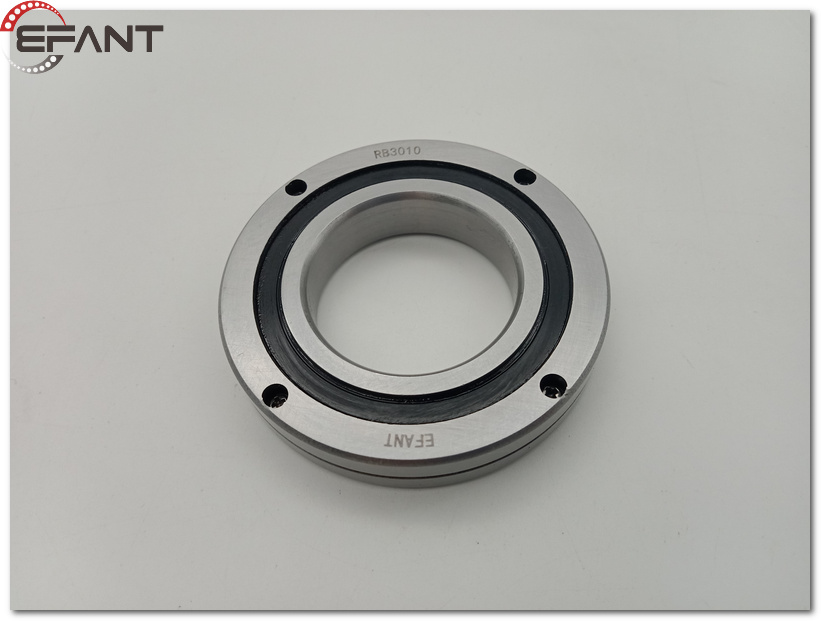

Luoyang EFANT Precision Bearing mainly to manufacture high-precision, high-rigidity,

heavy-load crossed roller bearings, rotary table bearings for 18 years. Our main products are RB, RA, CRBH, SX, RU, XU, XSU series crossed cylindrical roller bearings, YRT, YRTS, ZKLDF series rotary table bearings.

All bearings are processed by advanced CNC machine tools, ground three times by precision grinders, 100% inspected after each processing. All our bearings guaranteed for one year in

normal working condition. The inner diameter of the product ranges than 20 to 2000mm, and

most models have large stock. Bearing product catalogs are available for your quick selection, and

we can also recommend models according to specific working conditions.

Our company value is let our custom succeed. And we welcome you to visit our factory, so please feel free to contact us if you have any requirements and want to know more about us.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request