1.Proper Lubrication:

Ensure that the bearings are properly lubricated with the correct type and quantity of lubricant. Lubrication helps reduce friction and heat generation while preventing premature wear and failure.

2.Mounting and Installation:

Properly mount and install the bearings according to manufacturer recommendations. This includes ensuring proper alignment and clearance, as well as using the correct tools and techniques.

3.Alignment:

Spherical roller bearings are designed to accommodate misalignment. However, excessive misalignment can reduce their lifespan and lead to premature failure. Proper alignment is crucial for optimal performance.

4.Load Distribution:

Make sure the loads are distributed evenly across the bearing. Uneven loading can lead to premature wear and failure. Consider using shaft and housing fits that provide proper clearance and interference.

5.Temperature Management:

Monitor the operating temperature of the bearing. Excessive heat can damage the lubricant and the bearing itself. Use appropriate heat management techniques if necessary.

6.Sealing and Contamination:

Protect the bearing from contamination by using appropriate seals or shields. Contaminants such as dirt, moisture, and foreign particles can cause damage. Regularly inspect seals for integrity.

7.Vibration and Shock:

Be aware of the vibration and shock levels in your application. Excessive vibrations or shocks can lead to premature bearing failure. Use isolators or other methods to mitigate these issues.

8.Maintenance and Inspection:

Implement a regular maintenance and inspection schedule to check for signs of wear, damage, or other issues. Replace bearings as needed to prevent unexpected failures.

9.Load Ratings:

Ensure that the bearing's load ratings are suitable for your application. Exceeding the load capacity can lead to premature failure.

10.Environmental Factors:

Consider the environmental conditions in which the bearing operates. Factors like humidity, temperature variations, and exposure to corrosive substances can impact bearing performance.

11.Shaft and Housing Tolerances:

Follow the recommended shaft and housing tolerances provided by the bearing manufacturer. Incorrect fits can lead to premature wear and damage.

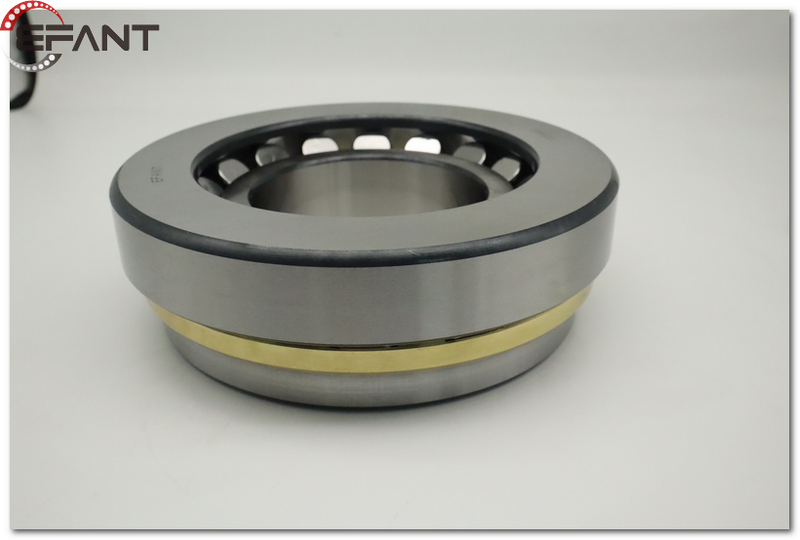

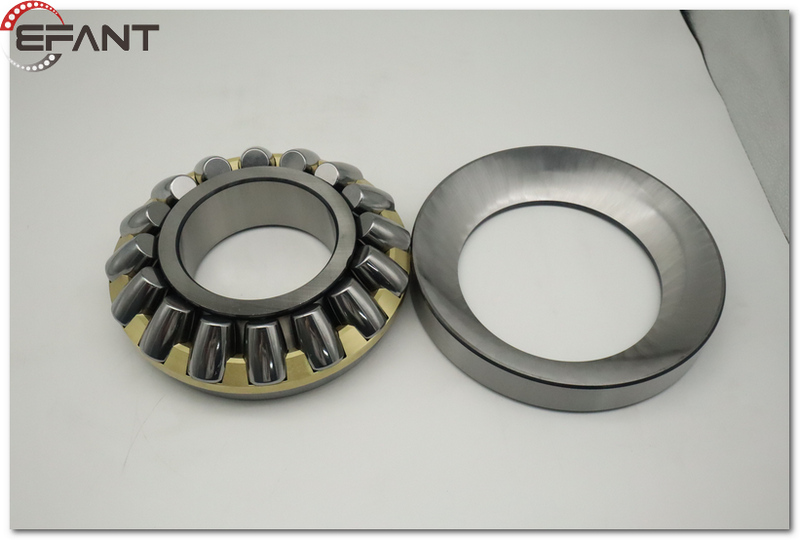

12.Bearing Selection:

Choose the right type and size of spherical roller bearing for your specific application. Consult with the manufacturer or an engineer to ensure the bearing meets your requirements.

13.Handling and Storage:

Handle and store spherical roller bearings carefully to prevent damage. Keep them in a clean and dry environment, and protect them from rust and corrosion.

Please do not hesitate to contact us with any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request