Slewing bearings are large bearings that can withstand combined loads and can withstand large axial, radial loads and overturning moments at the same time.

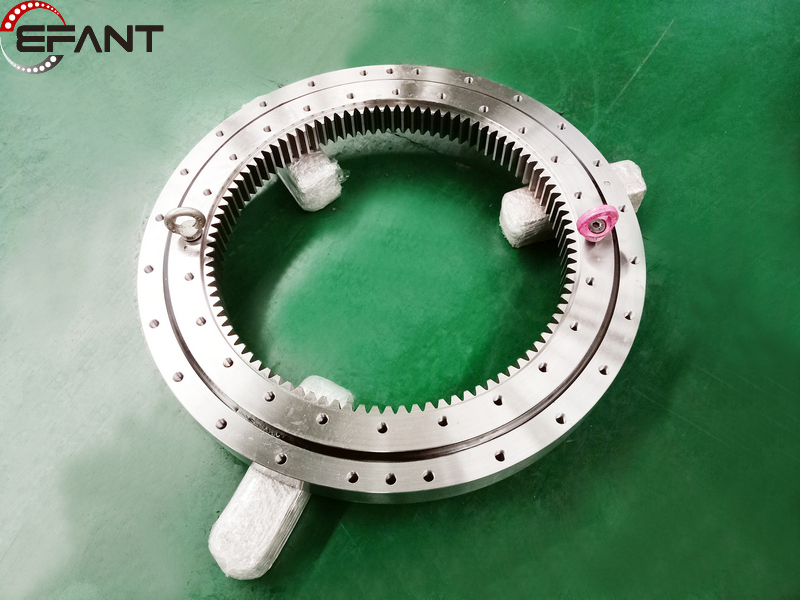

Slewing bearings generally have mounting holes, internal or external gears, lubricating oil holes and sealing devices, so that the main engine design structure is compact, easy to guide and easy to maintain.

Slewing bearings have four series: toothless, external and internal gear four-point contact ball bearings, double-row angular contact ball bearings, cross cylindrical roller bearings, cross tapered roller bearings and three-row cylindrical roller composite bearings. Among them, four-point contact ball bearings have higher static load capacity, cross cylindrical rollers have higher dynamic load capacity, and the pre-interference of cross tapered roller bearings can make the bearings have greater support rigidity and rotation accuracy. The three-row cylindrical roller combination bearings are led to the height of the bearings due to the increase in load capacity. Various forces are borne by different raceways. Therefore, under the same force, the bearing diameter can be greatly reduced, so it has the characteristics of making the main engine more compact. It is a slewing bearing with high load capacity.

Slewing bearings are widely used in large slewing devices of lifting machinery, mining machinery, construction machinery, port machinery, ship machinery, high-precision radar machinery, missile launchers, etc. At the same time, we can also design, develop and produce various special structure slewing bearings according to the specific requirements of users.

Please do not hesitate to contact us with any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request