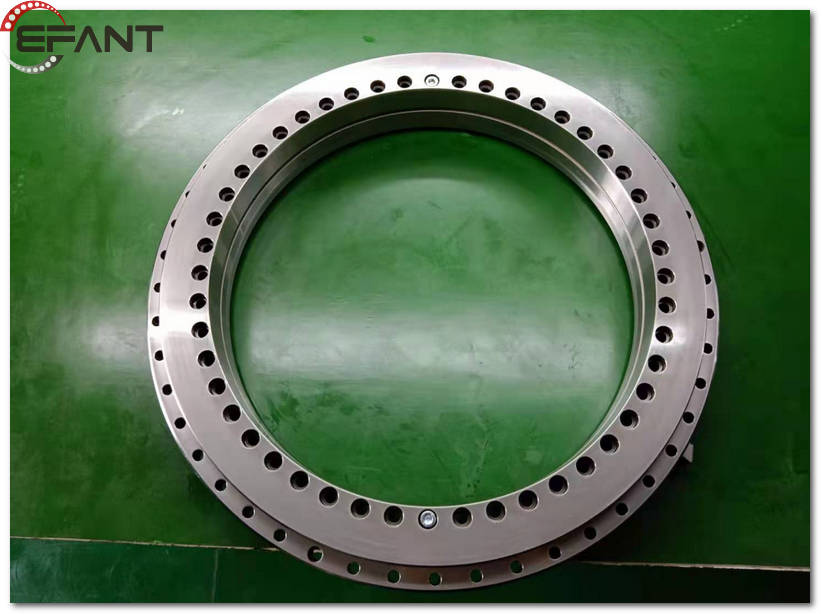

Rotary table bearing is a type of bearing similar to a three row roller combination slewing support structure. Compared to the three row roller combination slewing support structure, it has the characteristics of small size, high accuracy level, high rigidity, large load-bearing capacity, and resistance to damage. Mainly used in high-precision CNC turntables, CNC indexing discs, vertical machining centers, vertical grinders, military radars, precision medical equipment, etc.

Advantages of rotary tablee bearings:

1. The rotary table bearing has high-precision rotation performance. Due to the automatic centering of therotary table bearings, they have higher fault tolerance during installation and can withstand loads from various angles and directions. This high-precision rotation performance makes rotary table bearings widely used in various high-precision rotating machinery, such as CNC machine tools, high-precision grinding machines, measuring instruments, etc.

2. The rotary table bearing has high rigidity and high load-bearing capacity. The rotary table bearing adopts large diameter balls or rollers, which allows the bearing to maintain high rigidity even under heavy loads, reducing errors caused by deformation and improving rotational accuracy. Meanwhile, the rotary table bearings have a larger contact area and can withstand larger radial and axial loads, making them suitable for various heavy-duty industrial machinery and large rotating machinery.

3. The rotary table bearing has long service life and high reliability. Due to the use of high-quality materials and advanced heat treatment technology, the rotary table bearings have good wear resistance and corrosion resistance, which can ensure the long service life and stability of the bearings. In addition, the rotary table bearings also adopt a sealed design, effectively preventing the invasion of dust and impurities, further improving the reliability of the bearings.

4. The rotary table bearings are easy to install and maintain. The rotary table bearings have a compact structure and are easy to install. Simply select and install according to the specifications and dimensions of the bearings. At the same time, the rotary table bearings are also easy to maintain and upkeep, and the good performance of the bearings can be maintained through simple operations such as lubrication or replacing lubricating grease.

Disadvantages of rotary table bearings:

1. High maintenance requirements:

The rotary table bearings need regular lubrication and inspection to ensure their normal operation. Improper lubrication or insufficient maintenance may lead to premature bearing failure.

2. High cost:

Compared to ordinary bearings, the manufacturing and material costs of rotary table bearings are higher. In addition, its complex structure also increases production and maintenance costs.

3. Large size and weight:

Rotary table bearings are usually large in volume and heavy in weight, which requires the use of specialized equipment and methods during transportation and installation.

4. Noise and vibration issues:

In some applications, rotary table bearings may generate noise and vibration, which is a problem for equipment that requires quiet and stable operation.

Please feel free to contact us if you have any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request