Rotary table bearings are a type of mechanical component specifically designed to support and allow the smooth rotation of a rotary table or platform. These bearings are typically made of high-quality materials, such as steel or alloy, and are precision-engineered to provide maximum stability and durability.

What is the structure of the turntable bearing?

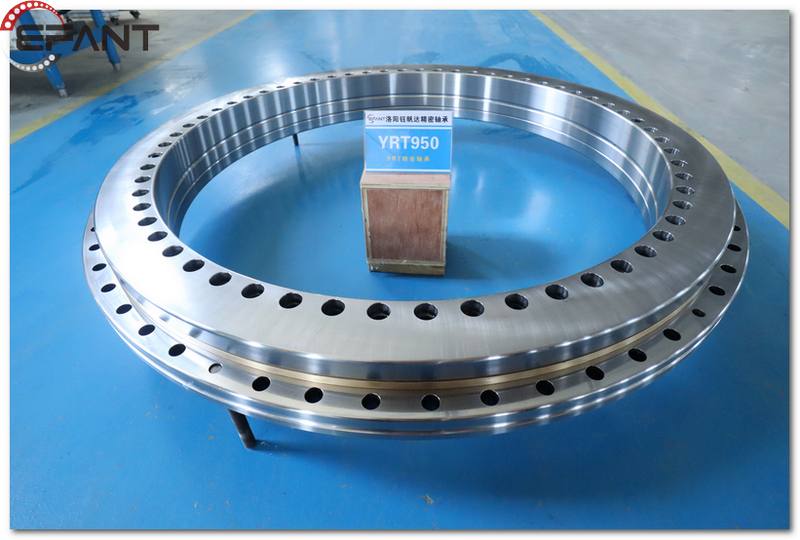

1.Inner Ring: This is the part of the bearing that attaches to the stationary structure, providing a mounting point.

2.Outer Ring: The outer ring is connected to the rotating structure, such as a platform or deck.

3.Rolling Elements: These are usually balls or cylindrical rollers that enable smooth rotation between the inner and outer rings. The rolling elements reduce friction and wear as the turntable rotates.

4.Raceways: These are the tracks or channels along which the rolling elements move. The inner and outer rings each have their own raceways, which are precisely machined to facilitate smooth movement.

5.Seals or Shields: These components help to keep contaminants out of the bearing and retain lubrication, thereby extending its lifespan and ensuring optimal performance.

6.Mounting Holes: Turntable bearings often have mounting holes or bolt patterns to facilitate installation onto the stationary and rotating structures.

7.Lubrication System: Lubrication is essential for reducing friction and preventing wear between the moving parts of the bearing. Some turntable bearings come equipped with built-in lubrication systems, while others require periodic manual lubrication.

What is the purpose of turntable bearings?

Rotary table bearings are widely used in various industries, including manufacturing, automation, and robotics. They are often used in machines that require precise and smooth rotation, such as CNC machines, lathes, milling machines, and grinders. These bearings help to ensure that the rotary table or platform maintains its position and does not wobble or vibrate during operation.

What are the characteristics of turntable bearings?

Rotary table bearings are characterized by their ability to support heavy loads, minimize friction for smooth rotation, provide precision in positioning, withstand harsh conditions, resist corrosion, feature compact designs, facilitate easy installation and maintenance, and offer versatility across various applications and industries.

Please do not hesitate to contact us with any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request