Here are the key stages and links in the production process of bearings:

1.Raw Material Selection:

Choosing high-quality raw materials, typically steel alloys or ceramics, is crucial for bearing performance. Steel is the most common material for bearing production.

2.Material Preparation:

The selected raw materials are melted and alloyed to achieve the desired properties and composition.

3.Forging or Casting:

The prepared material is either forged or cast into rough shapes, known as "billets" or "blanks," depending on the manufacturing process.

4.Heat Treatment:

Heat treatment processes like quenching and tempering are performed to improve the hardness, strength, and durability of the bearing components.

5.Machining:

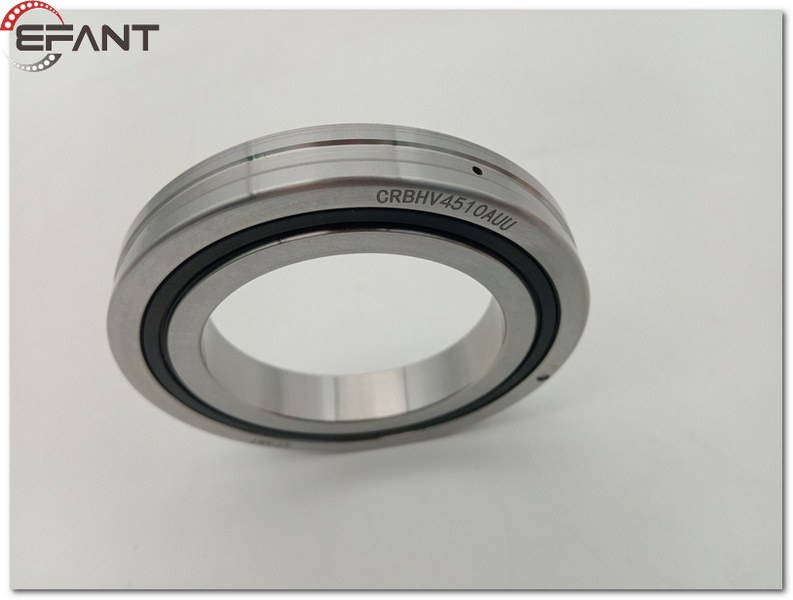

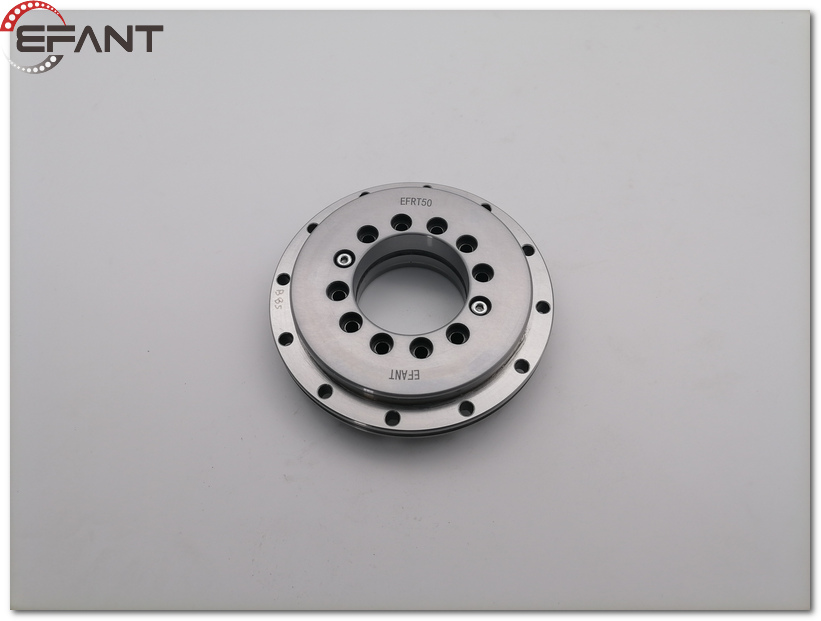

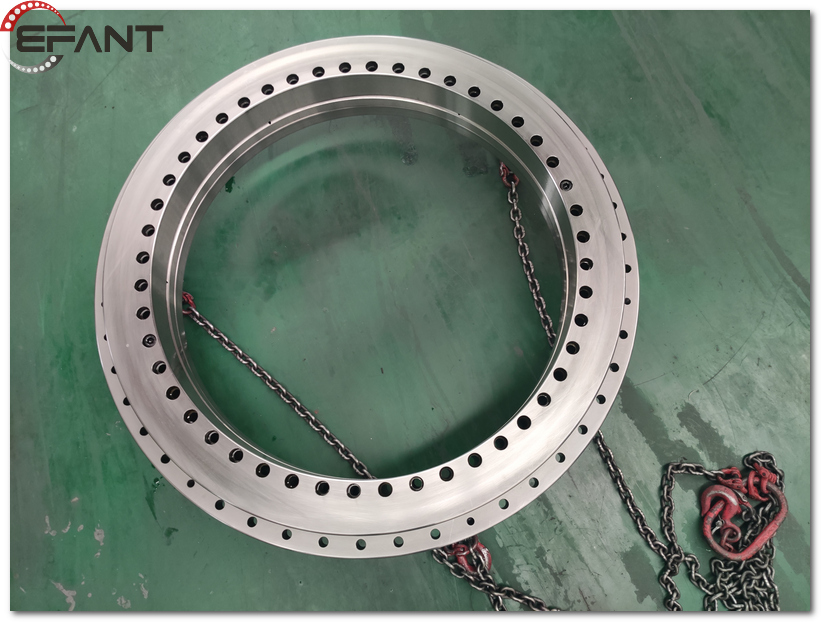

The billets or blanks are machined to precision dimensions and shapes. This includes turning, grinding, and milling operations to create the inner and outer rings, as well as the rolling elements (balls or rollers).

6.Assembly:

The inner and outer rings, rolling elements, cages (if applicable), and other components are assembled to create the bearing assembly.

7.Lubrication:

Bearings may be lubricated with grease or oil, depending on their application. Lubrication is essential to reduce friction and wear.

8.Quality Control and Testing:

Rigorous quality control and testing are performed at various stages of production. This includes dimensional checks, surface finish inspections, hardness testing, and noise/vibration testing.

9.Surface Treatment:

Surface treatments such as plating, coating, or nitriding may be applied to improve corrosion resistance and surface hardness.

10.Packaging:

Finished bearings are packaged to protect them during storage and transportation. Proper packaging ensures that the bearings reach customers in good condition.

11.Distribution:

Bearings are distributed to customers through various channels, including wholesalers, distributors, and direct sales to manufacturers.

12.Installation and Maintenance:

Customers install bearings in their applications and perform regular maintenance to ensure optimal performance and longevity.

13.Recycling and Disposal:

At the end of their service life, bearings can be recycled, and their materials can be reclaimed for reuse or environmentally responsible disposal.

Throughout the production process, quality control and traceability are critical to ensure that each bearing meets the required specifications and standards. Bearings play a vital role in various industries, including automotive, aerospace, industrial machinery, and more, so their production process is carefully monitored and optimized for performance and reliability.

You can contact us if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request