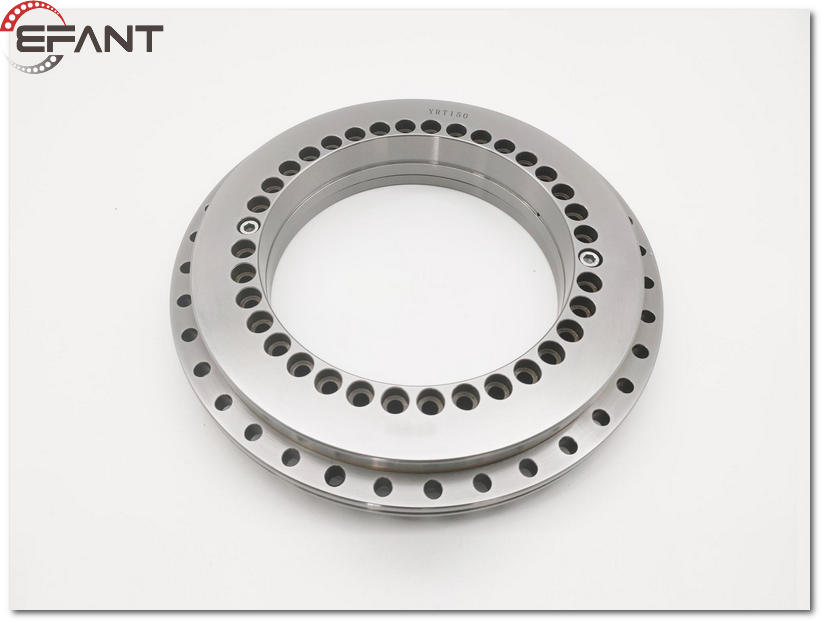

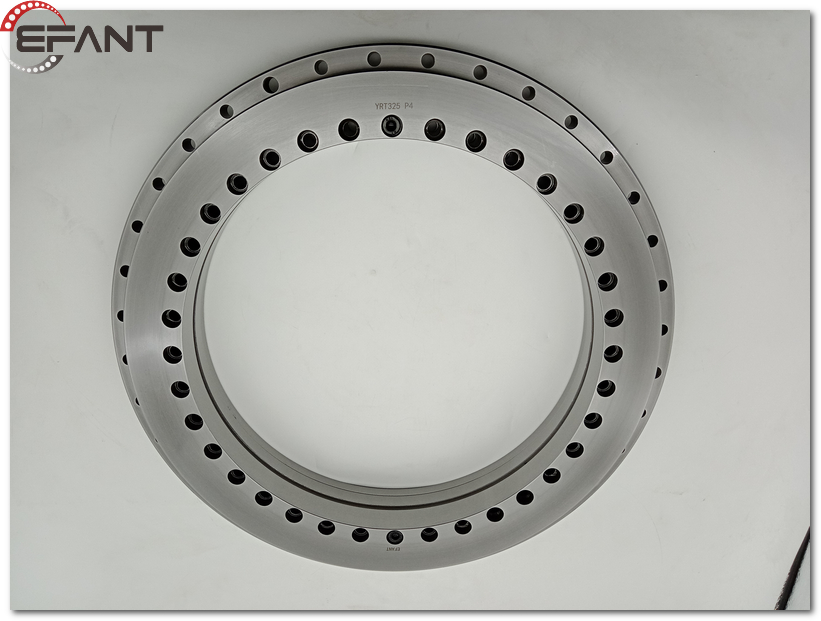

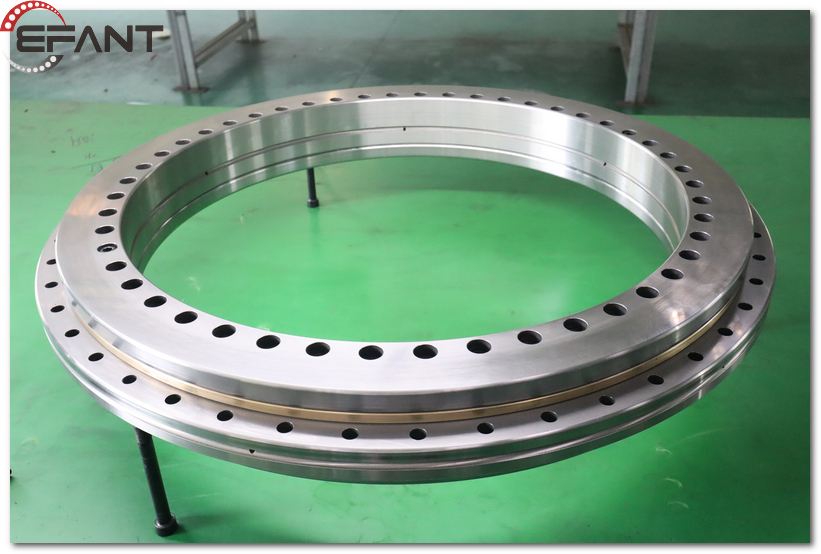

Identifying the quality of YRT (YRTM, YRTS) turntable bearings, which are high-precision axial-radial bearings used in various applications, requires careful evaluation of several key factors. Here are some important aspects to consider when assessing the quality of YRT turntable bearings:

1.Brand Reputation and Manufacturer: Start by researching and selecting reputable manufacturers or brands known for producing high-quality bearings. Well-established and trusted manufacturers often have a track record of delivering reliable and durable products.

2.Certification and Standards: Check if the YRT turntable bearings meet internationally recognized standards such as ISO (International Organization for Standardization) or ABEC (Annular Bearing Engineering Committee) ratings. Certification ensures that the bearings meet specific quality, precision, and performance requirements.

3.Material and Manufacturing Process: Examine the materials used in the construction of the bearings. High-quality YRT turntable bearings are typically made from premium-grade steel or other durable materials. Consider factors like heat treatment, surface finish, and precision machining processes used during manufacturing. A superior manufacturing process contributes to improved performance and longevity.

4.Load Capacity and Rigidity: Evaluate the load capacity and rigidity of the YRT turntable bearings. They should be able to handle the specific loads and forces expected in your application without excessive deflection or deformation. Higher load capacities and rigidity indicate better-quality bearings.

5.Precision and accuracy. Consider factors such as rotational accuracy, axial and radial runout, and repeatability. Bearings with tighter tolerances and lower deviation provide more precise positioning and enhance the overall performance of your application.

6.Lubrication and Sealing: Proper lubrication is crucial for bearing performance and longevity. Look for YRT turntable bearings that have efficient lubrication systems, such as built-in grease channels or lubrication holes. Additionally, seals or shields should be present to protect the bearings from contamination and ensure long-term reliability.

7.Noise and Vibration Levels: High-quality YRT turntable bearings should exhibit minimal noise and vibration during operation. Lower noise and vibration levels indicate better manufacturing precision and improved overall performance.

8.Warranty and Support: Consider the warranty and after-sales support offered by the manufacturer or supplier. A reputable brand usually provides a warranty period and responsive customer support, indicating their confidence in the product's quality and reliability.

9.Reviews and Feedback: Check for customer reviews, testimonials, or feedback about the specific YRT turntable bearings you are considering. Real-world experiences and opinions can provide valuable insights into the quality and performance of the bearings.

You can contact us if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request