Cross tapered roller bearings, also known as crossed roller bearings, are specialized rolling element bearings designed to provide high radial and axial stiffness in a compact design. They are commonly used in precision applications such as machine tools, robots, and industrial machinery where high accuracy and rigidity are essential. The processing of cross tapered roller bearings involves several steps:

1.Material Selection:

The first step in manufacturing cross tapered roller bearings is the selection of high-quality bearing steel or other suitable materials. The material must have excellent hardness, wear resistance, and fatigue resistance properties to ensure the bearing's longevity and performance.

2.Forging:

The selected material is forged into rough shapes that will eventually become the inner and outer rings of the bearing. Forging helps improve the material's grain structure and mechanical properties.

3.Turning and Heat Treatment:

The forged rings are then machined through turning operations to achieve the desired dimensions and tolerances. After turning, the rings undergo heat treatment processes such as quenching and tempering to achieve the desired hardness and toughness.

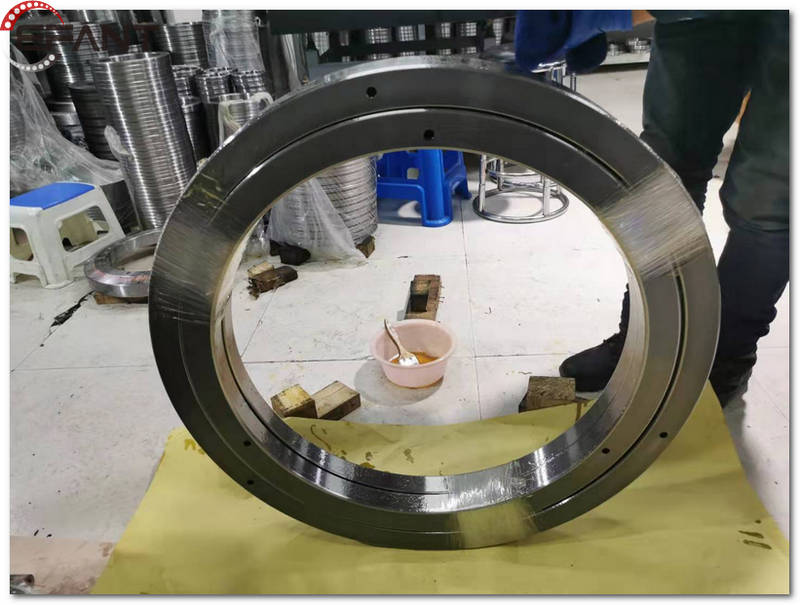

4.Grinding:

The inner and outer rings are precision-ground to achieve the required surface finish and dimensional accuracy. This step is crucial for ensuring smooth operation and minimizing friction within the bearing.

5.Assembly:

Cross tapered roller bearings consist of two sets of tapered rollers arranged at right angles to each other, housed within a cage. These components are carefully assembled with precision to ensure proper alignment and fit.

6.Lubrication:

Lubrication is essential for reducing friction and minimizing wear within the bearing. Depending on the application, the bearing may be lubricated with grease or oil.

7.Quality Control:

Throughout the manufacturing process, quality control measures are implemented to check for dimensional accuracy, hardness, and other critical parameters. Bearings are inspected to ensure they meet the required specifications and quality standards.

8.Packaging and Shipping:

Once the bearings pass quality control checks, they are packaged and prepared for shipping to customers or assembly into machinery and equipment.

It's worth noting that the manufacturing process for cross tapered roller bearings involves precision machining and quality control at every step to ensure the bearings meet the stringent requirements of precision applications. Properly processed and maintained cross tapered roller bearings can provide excellent performance, accuracy, and longevity in various industrial applications.

You can contact us if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request