Cross roller bearings are usually processed on CNC machine tools and precision machining equipment. Specifically, the equipment used to process cross roller bearings may include the following:

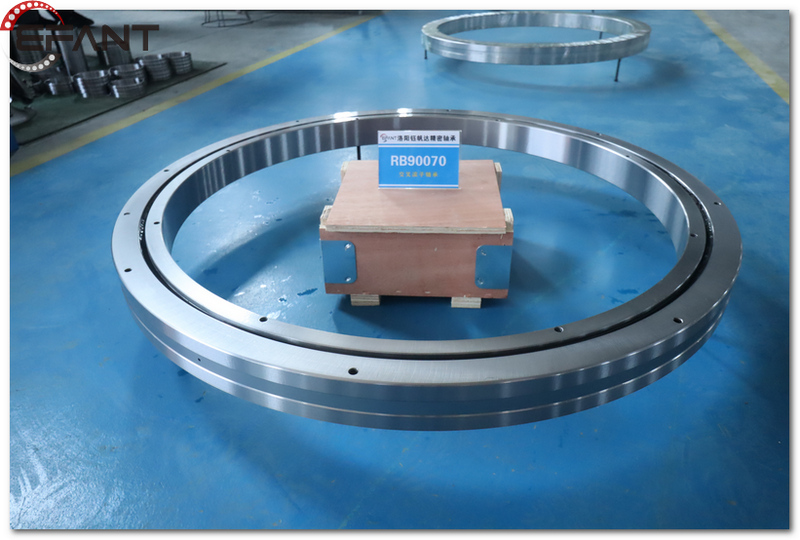

1. CNC lathe: used to process the precision dimensions of the inner and outer rings of the bearings, especially for larger cross roller bearings, CNC lathes are the main processing equipment.

2. CNC grinder: When processing key parts such as the raceway surface of the bearing, the plane of the inner and outer rings, the grinder can achieve high

3. Machining center: suitable for the processing of some complex shape parts of cross roller bearings, including drilling, milling and other operations.

4. Super finishing machine tools: The raceways of bearings often require extremely high precision and finish, so super finishing machine tools are needed to process the raceway surfaces to ensure low friction and high precision.

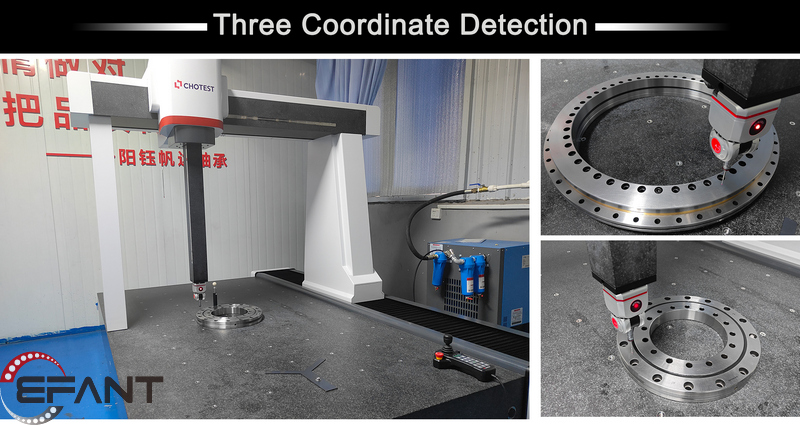

5. Assembly and testing equipment: After the bearings are processed, high-precision testing equipment, such as three-coordinate measuring machines, roundness meters, etc., are also required to detect their size, geometry and surface quality to ensure that the technical requirements are met.

Crossed roller bearings are widely used in precision mechanical equipment, such as industrial robots, CNC machine tool turntables, aerospace, precision optical instruments, etc., so high precision requirements are placed on the equipment and process during processing.

You can contact us if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request