The worktable of a machine tool usually requires bearings that provide high precision, stability and high load capacity to ensure smooth rotation and precise positioning. The following are several types of bearings commonly used in the worktable of a machine tool:

1. Crossed roller bearings

· Application: Widely used in rotary tables, indexing plates and precision turntables.

· Advantages: The rollers of the crossed roller bearings are arranged at 90 degrees, which can withstand radial, axial and overturning moments at the same time, providing high rigidity and high rotation accuracy.

Typical applications: Rotary tables of CNC machine tools, positioning turntables and other devices that require high-precision rotation.

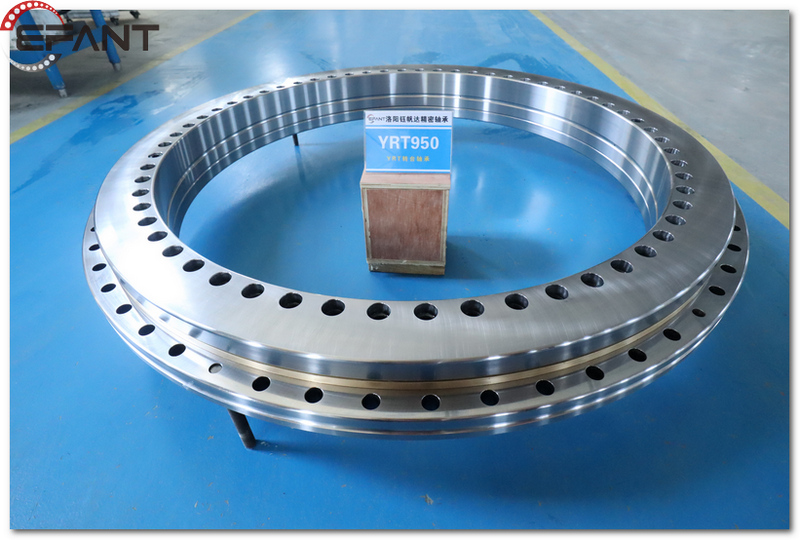

2. Slewing bearing (rotary table bearing)

· Application: Commonly used in heavy machine tools or large rotary worktables.

· Advantages: Able to withstand large axial, radial loads and overturning moments, usually compact in design and adaptable to large diameter structures, suitable for slow or medium speed rotation applications.

Typical applications: Such as rotary tables of large milling machines, lathes and workbenches of heavy equipment.

3. Precision angular contact ball bearings

· Application: Used for rotating platforms and workbenches that require high precision and high rigidity.

· Advantages: Has low friction and high-precision rotation performance, can withstand axial and radial loads, and is suitable for occasions that require high-speed and high-precision rotation.

Typical applications: High-precision indexing tables, rotary tables in machining centers, etc.

4. Thrust bearings

· Application: Suitable for rotary tables that need to withstand high axial loads.

· Advantages: Able to provide high-load axial support, especially suitable for situations with high axial forces.

· Typical applications: Thrust bearings may be used when heavy-duty tables of some machine tools require high axial support.

5. Hydrostatic Bearings

· Application: Used in rotary tables that require extremely high precision and low friction.

· Advantages: Produce suspension effect through liquid pressure, almost frictionless, smooth rotation, and extremely high rotation accuracy.

· Typical applications: High-precision rotary tables, such as the worktables in ultra-precision machining machines.

6. Sliding bearings

· Application: Used on some low-speed workbenches that require vibration resistance and smooth rotation.

· Advantages: Large friction resistance, but good stability and vibration resistance, suitable for low-speed, heavy-loaded workbenches.

Typical applications: Sliding bearings may be used in some low-speed, heavy-loaded large machine tool workbenches.

7. Rotary table bearing (precision bearing combination)

· Application: Used for rotary motion worktables that require high rigidity and high precision.

· Advantages: Usually combines the performance of angular contact bearings and cylindrical roller bearings, and can withstand high loads while providing high-precision rotation.

In summary, the selection of the right bearing depends on the function of the table, load requirements, rotation speed and precision requirements. For high-precision rotary tables, cross roller bearings or slewing ring bearings are usually used, while for applications requiring extremely high precision, hydrostatic bearings may be used.

If you have any needs, you can contact us at any time.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request