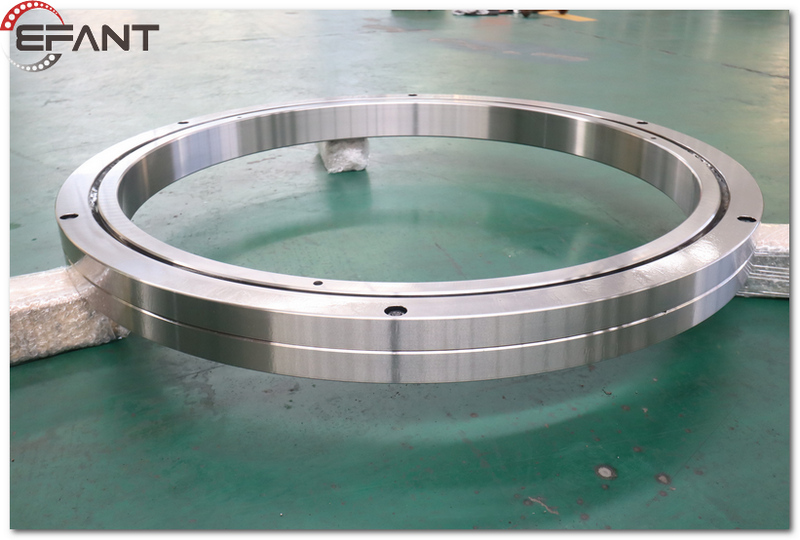

The processing of cross roller bearings on CNC lathes requires a high degree of precision because they are widely used in mechanical systems that require high precision and high rigidity, such as machine tool spindles, robot joints, precision rotary tables, etc. To process cross roller bearing parts on CNC lathes, the following key steps are usually included:

1.Prepare the processing procedure:

According to the design size of the bearing, a detailed processing procedure is formulated. The inner and outer rings of the cross roller bearing are usually annular structures, and the dimensional tolerance and surface roughness requirements are very high. Therefore, the processing procedure should pay special attention to parameters such as tool path, speed, feed rate, etc.

2.Material selection and blank preparation:

The use of high-strength materials, such as bearing steel (such as GCr15) or stainless steel, can ensure wear resistance and stability.

Before processing, the blank material is annealed or normalized to reduce work hardening and ensure that it is not easy to deform during cutting.

3.Rough processing (initial shaping):

Use CNC lathe for rough machining, including rough turning of outer diameter and inner diameter, to remove excess material and approach the target size.

After rough machining, the workpiece needs to reserve sufficient machining allowance for subsequent fine machining.

4.Semi-finishing and preheating:

Semi-finishing is performed to bring the inner and outer rings close to the final size, but still retain a slight machining allowance.

After this stage is completed, it is recommended to preheat or temper the workpiece to eliminate stress and make the workpiece less likely to deform during finishing.

5.Finishing (high-precision machining):

Use fine turning or fine grinding to further process the inner and outer rings to the design requirements.

This stage requires particularly high dimensional tolerance control, and usually uses high-precision tools and cutting parameters.

After turning, in order to obtain higher surface quality, the grooves or raceways of the inner and outer rings may need to be further ground using a special grinder.

6.Groove Processing:

The key part of the crossed roller bearing is its raceway, which requires precise cross grooves to be machined on the inner and outer rings to ensure that the rollers can be arranged at right angles when installed.

Raceway machining can be completed on a CNC grinder to ensure the shape accuracy and surface roughness of the groove.

7.Assembly and testing:

After all processing is completed, the inner and outer rings and rollers are assembled into finished products to ensure no errors and no interference.

Use professional testing equipment (such as roundness tester, roughness tester) to test the processed parts to ensure that they meet the design requirements.

Key Considerations

Tool wear: Pay attention to the wear state of the tool during processing, especially in the finishing stage. Tool wear will directly affect the dimensional accuracy.

Coolant: Using appropriate coolant can reduce the cutting temperature and reduce the thermal deformation of the workpiece.

Workpiece clamping: Ensure that the workpiece is clamped firmly to avoid vibration during processing and cause errors.

You can contact us if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request