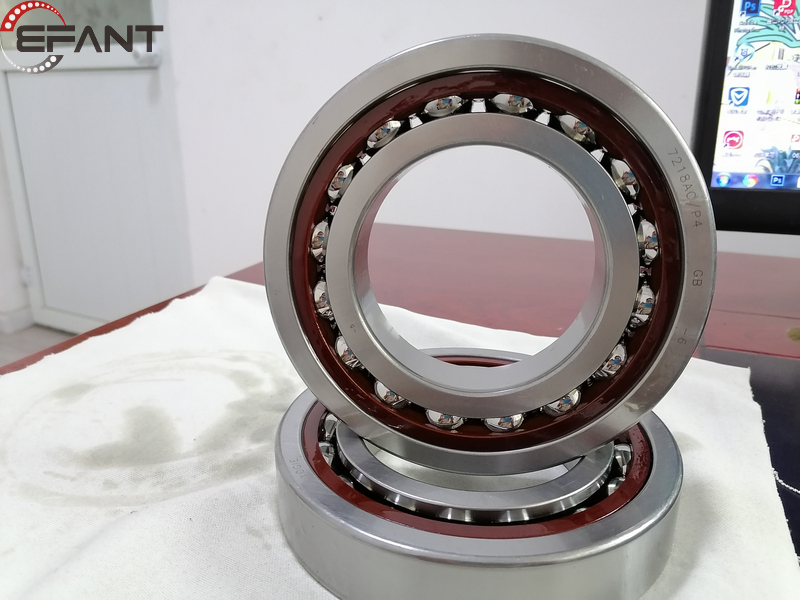

Angular contact ball bearings are a kind of bearing that can withstand the combined load-bearing capacity in both radial and axial directions. Compared with deep groove ball bearings, they have stronger load-bearing performance. They usually adopt the form of multiple sets of single-row or double-row bearings. Applications, especially in the field of machine tool type precision machinery and equipment, meet the requirements for high speed and high stiffness. The matching forms of angular contact ball bearings are as follows:

1.Back-to-back configuration: Two single-row angular contact ball bearings are installed back-to-back. Their contact angle lines will spread along the direction of the rotation axis, which can well withstand bidirectional axial load forces and have strong resistance to deformation. . This assembly method can provide the equipment with high rigidity and certain anti-overturning moment performance.

2.Face-to-face configuration: Two single-row angular contact ball bearings are installed face-to-face, and their contact angles will converge toward the direction of the rotation axis. Because of their small angular rigidity, they can effectively increase the preload.

3.Tandem configuration: Two single row angular contact ball bearings are installed in series. This means that their contact angle lines are in a parallel state, and the load forces from the radial and axial directions can be evenly shared by the bearings. However, this configuration usually only bears a single axial load force, and is usually installed at opposite ends of the machine to balance and limit axial stability.

4.Triple configuration: Three single-row angular contact triple installations, capable of bearing radial and axial loads in both directions at the same time. However, this assembly method is prone to uneven load distribution, especially under high-speed rotation conditions, which can easily cause damage to the bearings. Therefore, it usually cannot be used in high-speed rotation working environments.

5.Quadruple configuration: A quadruple installation of four single-row angular contact bearings can also withstand radial and axial load forces in both directions. Under the same internal clearance, its preload force and stiffness are twice that of ordinary assembly methods, so it can withstand larger ultimate axial loads.

6.Free configuration: Free configuration angular contact ball bearings need to strictly control the dimensional tolerance of the final grinding plane of the non-base surface of the outer ring to ensure that the width of the inner and outer rings is the same. This assembly method is used in the field of precision machine tools, and a certain preload can be obtained without complicated adjustments after installation.

Please feel free to contact us if you have any requirements.

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request