GCr15 steel, also known as 52100 bearing steel, is a high carbon chromium alloy steel commonly used in the manufacturing of bearings. It offers several advantages:

1.High Hardness: GCr15 steel has a high carbon content, which contributes to its excellent hardness. This high hardness makes it well-suited for applications where wear resistance and durability are crucial, such as in bearing components subjected to heavy loads and high speeds.

2.Good Wear Resistance: The combination of high carbon and chromium content in GCr15 steel results in good wear resistance. This property allows bearings made from GCr15 steel to maintain their shape and dimensions even under heavy loads and continuous friction, leading to extended service life.

3.High Fatigue Strength: GCr15 steel exhibits high fatigue strength, meaning it can withstand repeated loading and unloading cycles without experiencing premature failure. This property is essential for bearings operating in applications with constant or fluctuating loads, ensuring reliable performance over time.

4.Excellent Toughness: Despite its high hardness, GCr15 steel also possesses good toughness, which is crucial for withstanding impact and shock loads without fracturing. This toughness helps prevent catastrophic failures in bearing components and ensures continuous operation under demanding conditions.

5.Dimensional Stability: GCr15 steel has excellent dimensional stability, meaning it maintains its shape and size even under varying temperature and load conditions. This property is essential for achieving precise fit and alignment in bearing assemblies, leading to smooth operation and minimal vibration.

6.Corrosion Resistance: While GCr15 steel is not inherently corrosion-resistant like stainless steels, it can be treated or coated to enhance its corrosion resistance. This makes it suitable for applications where exposure to moisture or corrosive environments is a concern.

7.Wide Availability and Cost-Effectiveness: GCr15 steel is widely available and relatively cost-effective compared to some alternative bearing materials. Its combination of properties makes it a popular choice for a wide range of bearing applications across various industries, offering a balance of performance and affordability.

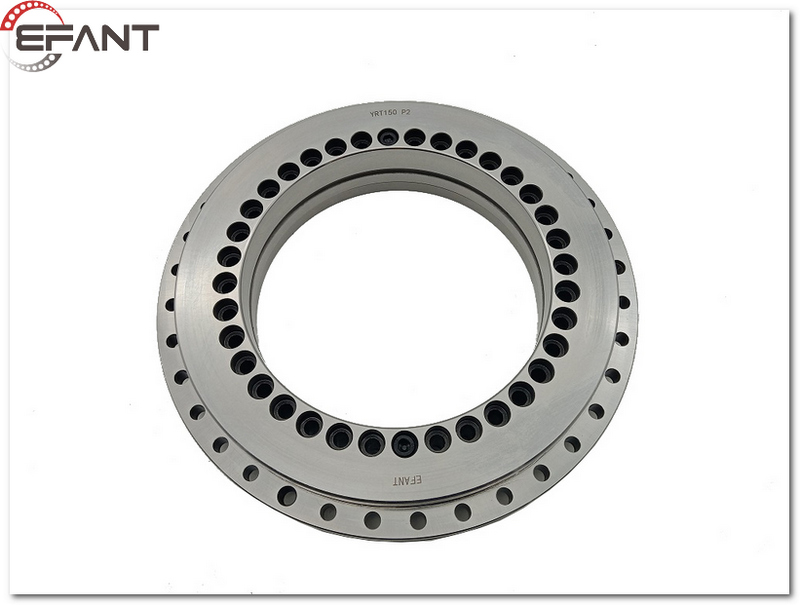

Our factory uniformly uses GCR15 bearing steel for bearings with inner diameters below 300 millimeters. We specialize in producing high-precision, high rigidity, and high load-bearing cross roller bearings, YRT rotary table bearings, harmonic reducer bearings, non-standard bearings, and a series of bearings that replace IKO, INA, SKF and other brands.

You can contact us if you have any requirements!

Dec-25-2024

Trade Shows&Event

Three things you should pay attention to when using turntable bearings! More InformationDec-24-2024

Trade Shows&Event

A brief introduction to the advantages of cylindrical roller bearings! More InformationDec-23-2024

Trade Shows&Event

What are the characteristics and applications of double-row cylindrical roller bearings? More InformationSubmit Request